DO YOU NEED

TO ASK OR ADVICE?

Do not hesitate to contact us

Products

Can lines

Output: 2 000 – 50 000 cans/hour

Can format: 0.25 – 0.7 l (according to customer requirements)

References:

PIVOVAR NYMBURK spol. s.r.o.

A challenge for us was the supply of a filling line assembly for filling beer into cans with the capacity of 15 000 cans per hour for our customer Pivovar Nymburk spol. s.r.o., with the production plant in Nymburk.

We have been cooperating with this customer for several years. In 2014, our affiliate supplied a crate depalletizer type NMD 1500 and a crate palletizer type NMP 1500.

Line assembly:

- Can depalletizing

- Can pack palletizing

- Intermediate pallet container

- Automatic wrapping machine

- Pallet labelling machine

- Pallet conveyors

- Safety fence for palletizing / depalletizing workplace

- Gravity rinser

- Can filler PEVAL 40

- Four-head can closing machine

- Central CIP station

- Can turning equipment

- Tunnel pasteurization machine

- Date-stamping equipment

- Automatic machine for packing cans in trays into foil

- Empty cans conveyors

- Full cans conveyors

- Group pack conveyors

- Line distributor

- Central lubrication - dry

- Fill level inspection (RTG)

Interesting facts about the line

Gravity rinser

- used for cleaning of packaging on the inside by rinsing before entering the filler

- continuous operation of the machine, interrupted rinsing - when the filler is halted

- connected to the can turner at the input and output

- used for cans of different height with the same diameter

- rinsing can be done using potable water, cleaning or disinfecting agents, steam or inert gas

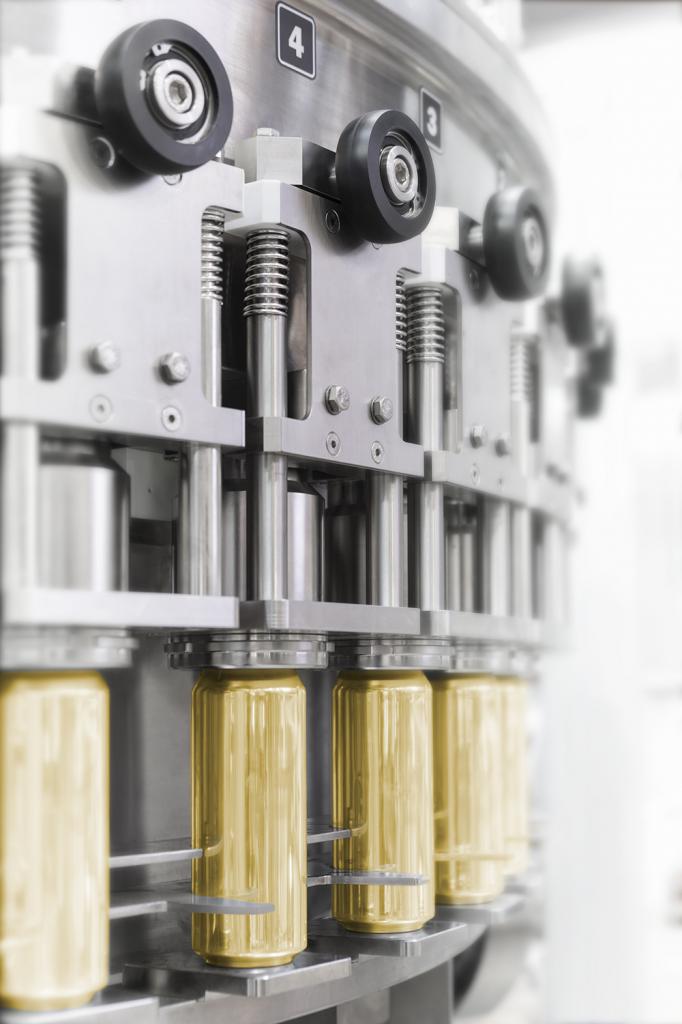

Can filler PEVAL 40

- overpressure level filler with pneumatically and electronically controlled valves

- minimum output 15 000 cans 0.5 l/hour

- the machine is fitted with 40 filling valves

- possibility of individual setting of filling process for every beverage type and can size - programming of rinsing time, filling speed and depressurizing

- liquid-control cone situated in the filler tank is free of springs, which means easier and more reliable sanitation

- discharge of CO2 from the can out of the filler tank before filling

Four-head closing machine

- separate can closing machine situated behind the filler, with secured synchronization with the filler and the inlet of cans on pull-through chain-driven apron conveyor

- can closing machine with the design for foam cleaning and rinsing of the neck space of a can before closing

|

|

AB Kalnapilis Brewery, Panevezhys, Lithuania

- Line for filling cans with an output of 10 000 BPH

Alibona a.s., Litovel, Czech Republic – Line for filling cans with an output of 5 000 BPH

- PEVAL 15 filler

- VSN 2 mixer

- Can conveyors

- Package conveyors